In March 2020, Xi 'an's first kitchen waste treatment plant has been put into operation for the first year. The kitchen waste plant can convert 200 tons of kitchen waste and 20 tons of cooking oil into biogas and crude oil every day. Such excellent performance, behind the efforts of Willy!

Want to know how Willy managed to turn kitchen waste into treasure? Let's take a look!

Turn waste into treasure

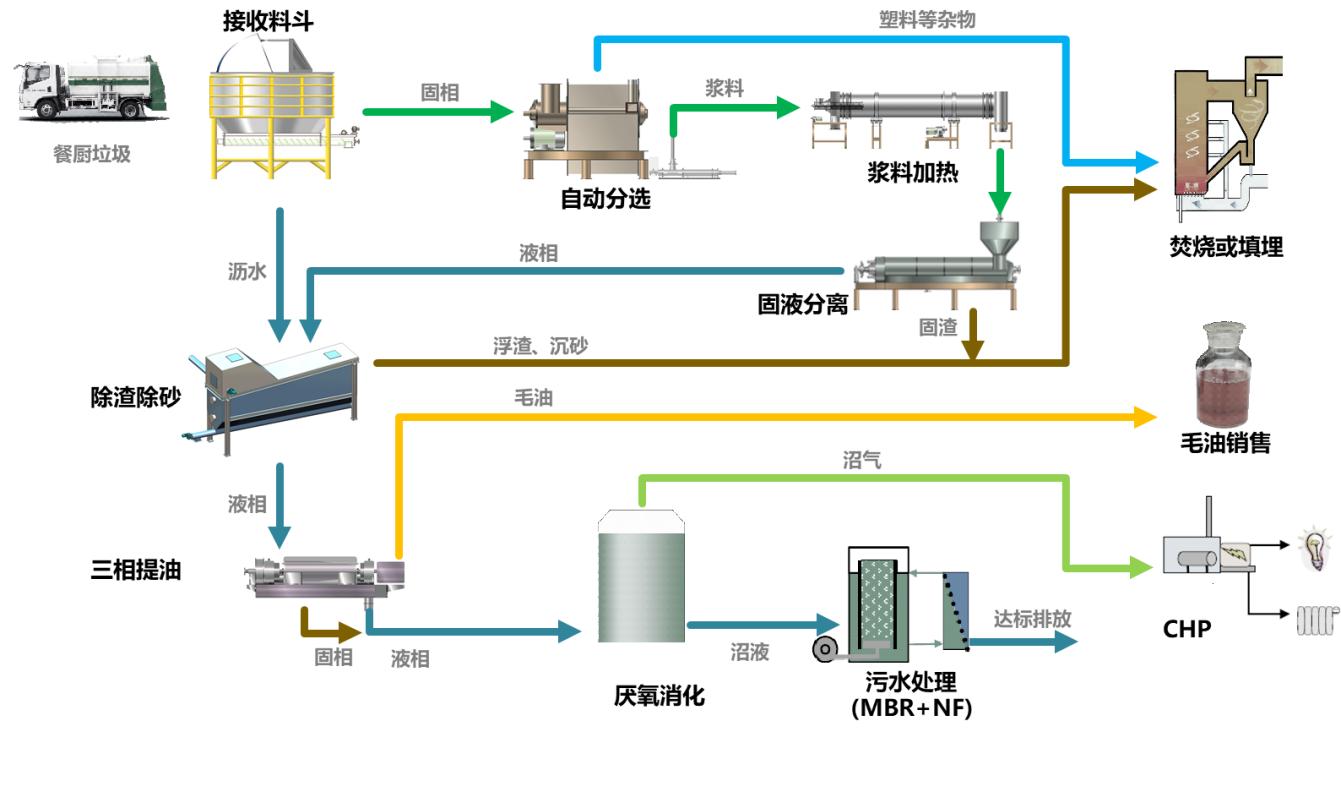

After measuring and weighing, the food and kitchen waste collected from the streets and alleys of Xi 'an is unloaded into the receiving hopper and enters the disposal system as shown in the figure below.

Kitchen waste treatment process diagram

In order to more fully extract grease and convert organic matter into biogas, kitchen waste must first go through a series of processes such as "automatic sorting - slurry heating - solid-liquid separation".

Automatic sorting is mainly to separate the plastic, fabric and other large debris in the kitchen waste, and at the same time break the organic matter that can anaerobic marsh. The coarse stock formed enters the stock heating equipment.

There are two main functions of slurry heating: First, after heating the organic slurry, it is beneficial to maximize the recovery of oil recovery process; Secondly, under the action of high temperature and mechanical agitation, the solid organic matter in the slurry can be separated into the liquid phase to the maximum, and the solid phase amount is also reduced.

After the slurry is heated, the material is separated by solid and liquid, the solid slag is sent to incineration, and the kitchen slurry is treated by slagging and sand removal, so that oil extraction and anaerobic digestion can be carried out.

The purity of crude oil separated from kitchen waste can reach more than 97%, which can be sold as industrial raw materials. The biogas generated by anaerobic digestion can be used for power generation, and the waste heat from power generation can also be recycled in the form of steam.

Kitchen waste pretreatment workshop

Central control room

Experience exchange

According to the local dietary characteristics of Xi 'an, compared with other areas, the content of grease and organic matter in the kitchen waste produced in this area is higher. Therefore, the operation of Xi 'an Kitchen project has accumulated special experience for the disposal of kitchen waste in Northwest China.

Due to the particularity of waste in Xi 'an, the SS of anaerobic biogas slurry after centrifugation and dehydration is still high, and it is difficult to treat sewage. This project has high requirements for sewage treatment discharge standards. Based on the comprehensive analysis of the existing experience in the treatment of kitchen waste wastewater, through the unremitting efforts of the project team, improvements have been made in the sewage treatment tank capacity design, aeration air volume design, aeration head selection and other aspects to ensure that the effluent discharge meets the standards, and further optimize the sewage treatment design parameters of the kitchen project.

The quality of odor management is an important part of judging the success of kitchen waste project. The residential area near the kitchen project in Xi 'an is close to the factory area, so the odor management of the project is particularly important.

Through multi-directional deodorization measures, the project team ensured a good factory environment, avoided adverse effects on the lives of surrounding residents, and further enriched the design and operation experience of odor management of kitchen waste treatment projects.

Results display

At present, the project has signed garbage recycling contracts with 1,300 restaurants, canteens, authorities, schools and other units, covering the six districts of Xi 'an City and Xixian New District, economic development District, Qujiang New District, Ba Qiao District, etc., the scope of collection and transportation covers provincial and municipal organs, college canteens, comprehensive commercial buildings and dining units of more than 200 square meters.

Since the project was put into operation for one year, the average daily disposal capacity of kitchen waste in normal times has been 204 tons/day, and the average disposal capacity of gutter oil has been 10 tons/day. The average daily output of biogas is 16944 square meters/day, and the average gross oil output is 17.7 tons/day (including gutter oil). In the special period of the novel coronavirus pneumonia, the amount of food waste into the factory has been greatly reduced. With the basic end of the epidemic in China, the catering industry will gradually resume business, and the amount of food waste disposal will gradually return to normal levels.

In addition, the second phase of the Xi 'an Kitchen project has obtained planning permission, and the disposal capacity of kitchen waste will reach 400 tons/day after the completion of the second phase of the project.

Visit the exhibition hall

Xi 'an Kitchen Project realizes the resource utilization of kitchen waste and waste oil, and can also live in harmony with the surrounding environment. The project is the Ministry of Ecology and Environment, the Ministry of Housing and Urban-Rural Development jointly announced the second batch of national environmental protection facilities and urban sewage waste treatment facilities open to the public, has welcomed a number of people to visit, you can make an appointment, walk into the site to further understand the process of kitchen waste treatment plant resources.