If urban and rural organic waste is properly handled, it can greatly reduce environmental pollution while providing energy and resources.

As a leader in the domestic biogas and biogas industry, Hangzhou Energy and Environmental Engineering Co., LTD., a wholly-owned subsidiary of Welly Environmental Protection Group, is committed to providing organic waste treatment and resource recovery solutions, converting organic waste into clean energy and organic fertilizer, which can not only effectively control the pollution caused by organic waste, but also help the development of circular agriculture. Now, let's walk into Xuzhou Guoxin large-scale organic waste Treatment Center (hereinafter referred to as "Xuzhou Guoxin Project"), which is built by Hangneng Environment general contract to understand the resource treatment of organic waste!

Project background

Xuzhou Guoxin Project, located in Peixian County, Xuzhou City, Jiangsu Province, is a project that takes into account environmental protection clean energy supply, organic fertilizer supply and greenhouse gas emission reduction. It was completed and accepted in September 2019 and officially put into production. The project is a large-scale biogas project within the central budget in 2017.

Xuzhou Guoxin Project is expected to handle 360,000 tons of livestock and poultry manure, 24,000 tons of sanitation manure, 20,000 tons of straw and 14,000 tons of kitchen waste annually, with an annual output of 19.8 million cubic meters of biogas, part of which is purified into biological natural gas with an annual output of 7 million cubic meters and connected to Peixian Ganghua Gas Pipeline, and the other part is burned for power generation with an annual output of 15.8 million KWH. Electricity is connected to the grid, and waste heat generated by power generation is recovered. The biogas residue produced after anaerobic fermentation can be used as raw materials for the production of solid organic fertilizer, with an estimated annual output of 35,000 tons of solid organic fertilizer and compound fertilizer and 300,000 tons of biogas slurry, providing more options for surrounding farmers. Heat and power fertilizer co-production, to achieve the diversification of products, the formation of "biomass - biogas - natural gas - power generation - fertilizer" circular economy industry chain.

The Xuzhou Guoxin project combines the actual requirements of animal husbandry and agricultural development and environmental protection in Peixian County, and the raw materials treated include livestock and poultry manure, sanitation manure, straw and kitchen waste, realizing the coordination of multiple raw materials and the overall resource treatment of urban and rural organic waste.

Solutions and technical advantages

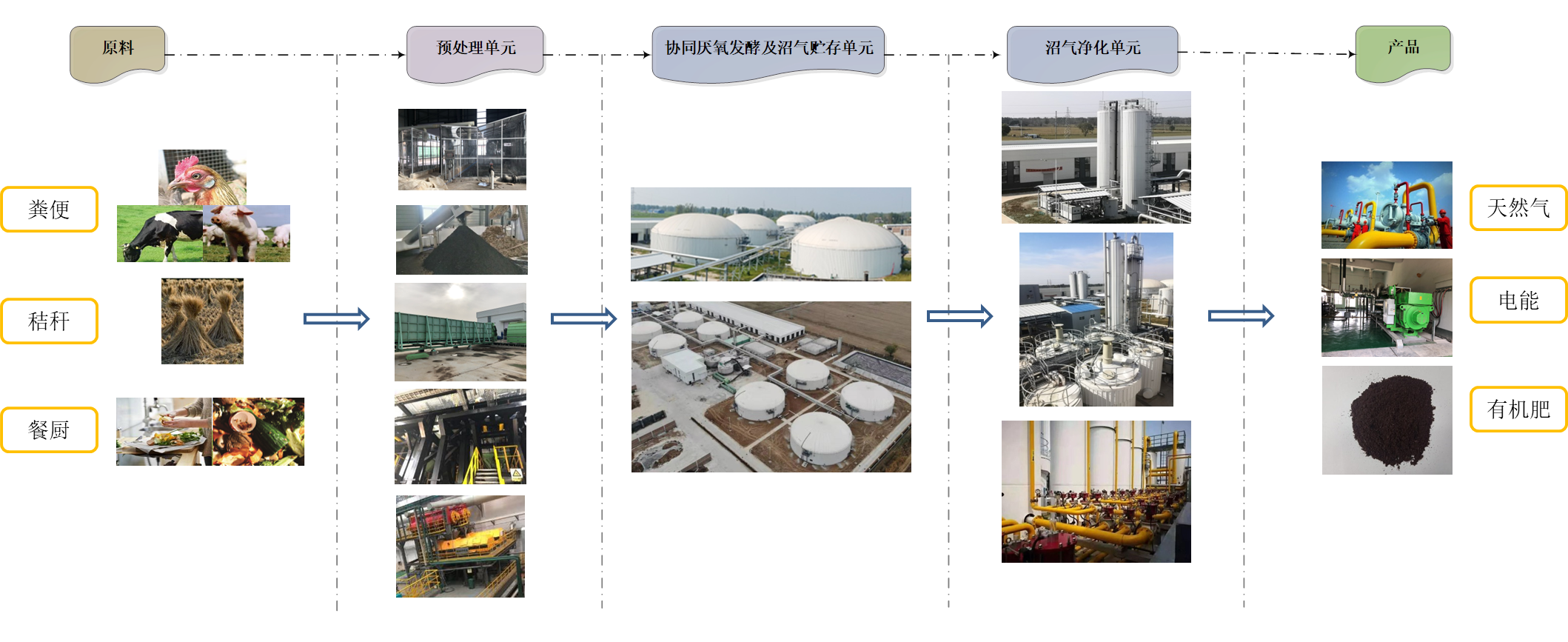

Xuzhou Guoxin project receives and transport raw materials within 30km around the factory to the factory, and the raw materials enter the processing system as shown in the figure below, and finally produce products that can be sold.

Technological flow diagram of Xuzhou Guoxin project

预处理单元将不同性质的各原料分开处理。粪便采用槽罐车运至预处理车间,考虑到鸡粪中会混有一定量的砂石,采用水解除砂工艺去除粪污中的砂石进行预处理。厂区内黄贮处理后的秸秆经过破碎机破碎后,进入水解池。

Spiral sand removal device in pretreatment workshop

Straw pretreatment unit

Anaerobic fermentation unit

The anaerobic fermentation treatment system of the project adopts the medium temperature integrated CSTR anaerobic fermentation process. The fermentation process is stable, easy to manage, easy to start and low operating cost by using stirring and warming technology in the fermenter. Moreover, the integrated biogas fermentation device integrates anaerobic fermentation and gas storage, does not need to be equipped with a separate gas storage tank, saves land and has relatively low project investment.

Integrated CSTR anaerobic fermenter

Biogas produced by anaerobic fermenters is a mixture of saturated water vapor, containing H2S and suspended particulate impurities in addition to gaseous fuels CH4 and CO2. H2S in biogas is not only toxic, but also highly corrosive, and excessive H2S and impurities will endanger the life of subsequent equipment.

The biogas is pretreated by biological desulfurization process. After biological desulfurization, one-third of the biogas is burned by a generator to generate electricity, and the other two-thirds of the biogas is purified by pressure shift adsorption (PSA) to produce biogas.

After the initial purification treatment, the biogas is sent to the pressure shift adsorption unit area. First, the hydrogen sulfide in the biogas is removed to less than 10ppm by dry desulfurization and filtration, and then pressurized to 0.5Mpa·G by the biogas compressor, the gas liquid is separated and the oil is removed by decarbonizing device, and the impurity gases such as CO2 and H2O in the biogas are removed. The final qualified product gas is connected to the gas pipeline.

Biogas biological desulfurization and pressure swing adsorption purification unit

Achievement and significance

At present, Xuzhou Guoxin project is serving the surrounding 8 towns, has more than 500 large-scale farmers into the collection and transportation system, the daily collection and transportation of about 800 tons, is expected to reach the summer of 2020, can achieve all receivable. In addition, more than 700 restaurants in the county have signed a collection and transportation agreement with Xuzhou National New Project, and feces from surrounding public toilets and septic tanks in the community will also be collected and treated. The next step of the project is to gradually increase stalks, carry out anaerobic fermentation, and improve the resource treatment and high-value utilization of crop stalks in Peixian County.

The completion of Xuzhou National new project and the gradual production, so that the livestock and poultry manure in the surrounding towns can be daily clear, so that the feces do not leave the house, do not stay overnight, to achieve external "zero emission", the surrounding area of kitchen waste, sanitation feces, crop straw will also be transformed into waste treasure through resource utilization, all into biological natural gas and electric energy. Finally, environmental benefits, social benefits and economic benefits can be achieved.

Xuzhou Guoxin project has been selected as a medium - and long-term biological gas development planning project in Jiangsu Province, which caters to the trend of large-scale and standardized planting and breeding. Focusing on large livestock counties and large-scale livestock farms, taking biogas, biological gas and electric energy as the main processing direction, and agricultural organic fertilizers and rural energy as the main utilization direction, is the necessary supporting facilities for the development of modern agriculture.