Bangkok 800 tons/day domestic waste comprehensive treatment project (hereinafter referred to as the "Thailand project") is located in the beautiful "City of Angels" - Bangkok, Thailand, by the consortium of Welli Environmental Protection Group, the group's wholly-owned subsidiary Thailand Welli and Thailand's local enterprise E-Square jointly undertaken, but also the first overseas municipal waste comprehensive treatment project undertaken by Welli.

Project background

The Thai project adopted MYT (Maximum Yield Technology) process to treat domestic waste in Onnut District of Bangkok City. Changzhou Jinyuan Machinery Equipment Co., LTD., a wholly-owned subsidiary of Welly, is responsible for the equipment manufacturing and on-site installation technical guidance of the project. The total occupation area of the plant is 32,000m², and the domestic waste disposal capacity is 800t/d. At present, the project has been debugged and entered the formal operation stage. The completion of the Thailand project has provided the Group with rich project experience to continue to expand overseas markets.

Solution

Technology:

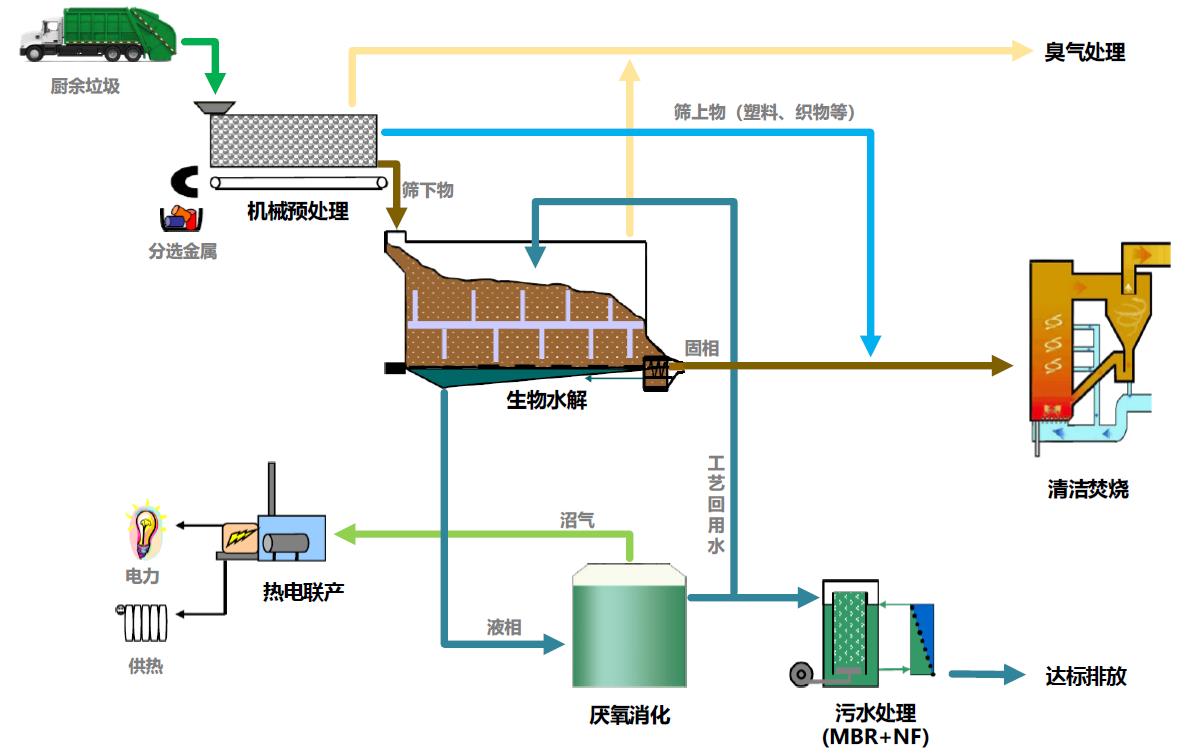

The processing process of this project is: "mechanical pretreatment + biohydrolysis + anaerobic digestion + biogas power generation +RDF utilization".

Process flow chart

The domestic waste in Onnut district of Bangkok is a mixed collection, containing kitchen waste, plastic, fabric, metal and other debris, and the composition is more complex. With the change of seasons, the moisture content of waste also changes correspondingly, which is not suitable for direct incineration treatment, but after the treatment of MYT technology, domestic waste can be converted into RDF and biogas, which can be used for energy utilization respectively.

RDF will be used for energy. Compared with the original refuse, RDF has the characteristics of low moisture content, uniform material and high calorific value, which is more conducive to the control of the combustion process and can effectively reduce the generation of secondary pollution. In the treatment process, the biogas generated by anaerobic fermentation is pre-treated for cogeneration, and the generated electrical energy is partly used for the operation of the factory equipment, the remaining electric energy is sold online, and the waste heat of power generation is recovered for the heating and insulation of the anaerobic system, realizing the ecological energy utilization of domestic waste.

Core technology and equipment:

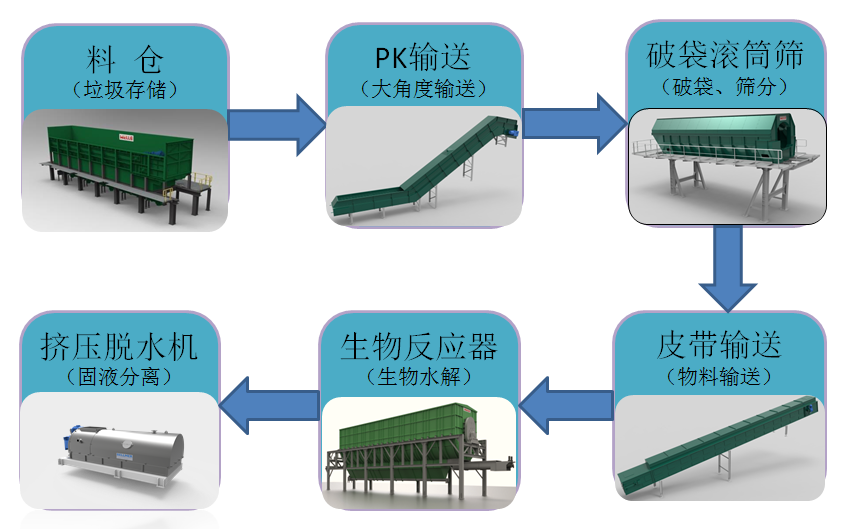

(1)Pretreatment technology and biohydrolysis reactor

Changzhou Jinyuan Machinery Equipment Co., LTD., a wholly-owned subsidiary of Welly, according to the actual needs of the project in Thailand, fully taking into account the local material characteristics and geographical location and other factors, summarizes the previous project experience, uses the technical advantages of the parent company, provides customers with high-end environmental protection equipment solutions, and works together to solve the problem of "garbage besieged city".

Jinyuan Machinery provided a complete set of pretreatment equipment for the project, such as silo, roller screen, closed belt conveyor, etc. In addition, the core equipment was also supplied by Jinyuan biohydrolysis reactor, which is a complete localization of German technology by Jinyuan, and optimized and improved in combination with Southeast Asian garbage characteristics, greatly reducing equipment costs and improving equipment adaptability and reliability.

(2)High efficiency anaerobic reactor and biological desulfurization technology

The Thai project has designed four sets of 4000m³ efficient anaerobic reactors and two sets of 1000m³/h biological desulfurization systems. All of them are designed, supplied and installed by Hangzhou Energy and Environment Engineering Co., LTD., a subsidiary of Weley Holdings. The high efficiency anaerobic reactor has the characteristics of high load, low residence time, high efficiency and high gas production rate, and the amount of biogas residue is less than that of the traditional CSTR reactor. Biological desulfurization technology has the advantage of low operating cost. The combination of the two technologies realizes the utilization of organic resources at low cost and high efficiency.

(3)High pressure reverse osmosis equipment

In order to meet the strict sewage discharge standards of the Thai project, the high pressure reverse osmosis system (HPRO) is also designed and supplied by Willy.

Project significance

The Thailand project is the world's largest solid waste treatment project using MYT technology and the first MYT project to be built in Southeast Asia. It can process 800t of domestic waste per day, produce 40000m³ of biogas, and produce about 500t of derived fuel (RDF). The Thai project solves the problem of "garbage besieged city" in onnut District of Bangkok, avoids the pollution and damage caused by domestic waste to the local ecological environment, and maximizes the ecological energy utilization of domestic waste.

The project is an important milestone in the application and development of MYT technology, reflecting the international market's recognition of MYT technology in the field of domestic waste and kitchen waste recycling. It is of great significance for the treatment of waste with complex composition and high moisture content in China and Southeast Asia.